How To Keep Brake Rotors From Rusting During Storage

As you lovingly tuck your car away for the season, it’s easy to overlook a critical component that often bears the brunt of neglect—your brake rotors. Rusty rotors affect driving performance and can lead to steering wheel vibrations, impacting braking efficiency.

So, on a crisp autumn afternoon, sitting in the garage, surrounded by the intoxicating scent of motor oil, thinking about how to keep brake rotors from rusting during storage? Navigating the intricate world of brake rotor storage might sound daunting, but fear not. Today, I’m not just your typical car care guide; think of me as your trusty pit crew member.

From cleaning and coating techniques to proper storage methods, I’m here to simplify the process, share some insider tips, and make sure your ride stays in top-notch condition. I will help you ensure your prized possession gets the love and attention it deserves.

Understanding Brake Rotors and Rust

Brake rotors, typically made of iron or a composite alloy, are vulnerable to oxidation. When these metals are exposed to moisture, a chemical reaction occurs, leading to the formation of iron oxide, better known as rust.

What Causes Brake Rust

Rotor rust occurs due to environmental moisture (summer or winter in both seasons), which can build up during normal driving (road salt) and accelerate rusting in poorly ventilated conditions.

Accelerated by the braking heat generated during regular use, it creates the perfect storm for rust to silently creep onto the surface of your rotors. And the battle against rust doesn’t conclude on the open road; rust can attack idle rotors sitting in the garage as well.

Moisture, whether disguised as humidity or rainwater, proves to be a cunning infiltrator, penetrating even under car covers in the most well-protected garages and instigating rust formation. Let’s not forget the residual brake pad residue on parking brakes, which, when left unattended, becomes a breeding ground for corrosion.

It’s this trio of moisture, exposure, and brake pad residue that conspires against your brake rotors during storage.

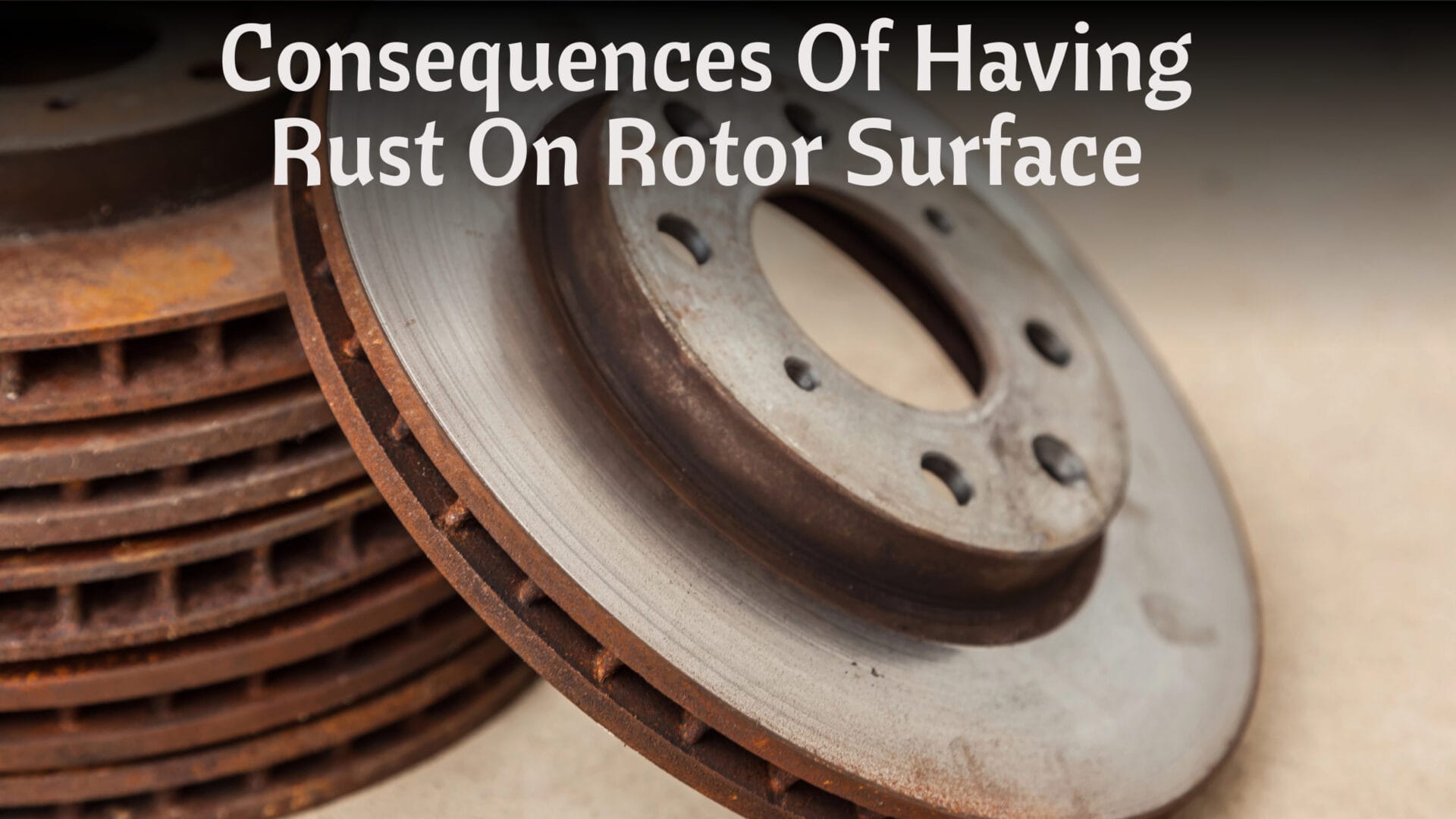

Consequences Of Having Rust On Rotor Surface

So, what’s the big deal with a little rust on your brake rotors? Well, buckle up for this reality check: rust on your brake rotors isn’t just a cosmetic issue; it’s a performance and safety concern. As rust forms, it compromises the smooth surface of the rotors, hindering the effectiveness of your braking system.

The consequences extend beyond mere aesthetics, potentially leading to pulsating brakes, increased stopping distances, and, in extreme cases, compromising your vehicle’s overall safety.

However, if there’s only a little rust on the rotor surface, there’s nothing to worry about. A ride of a few miles will vanquish the rust, but if it’s deep rust, it can lead to potential hazards. Deep rust can potentially lead to corrosion, pulsating brakes, increased stopping distances, compromising your vehicle’s overall safety, and potentially causing brake caliper attachments.

Furthermore, deep rust can result in brake rotor warping, creating the need for replacement. Addressing deep rust promptly can prevent these consequences and maintain the integrity of the rotors, saving costs and ensuring safety.

How To Keep Brake Rotors From Rusting During Storage

Proper brake rotor storage prevents rusting, requiring a dry and clean environment to shield from moisture. Additionally, applying the anti-rust spray and using brake rotor covers can prolong their lifespan. It’s essential to store brake rotors in a moisture-free space to prevent corrosion and ensure longevity.

Let’s know in detail through a step-by-step guide.

Choose a Suitable Storage Spot:

Begin by selecting a dry and well-ventilated storage location that is away from extreme temperature fluctuations. A garage or a covered area is an ideal place to shield your brake rotors.

Clean Each Rotor:

Prior to storage, give each brake rotor a thorough cleaning. Use a brake cleaner or mild detergent to remove any accumulated dirt, brake pad residue, or road grime.

Apply Rust-Preventing Oil:

Take preventative measures by applying rust-preventing oil to each brake rotor, forming a protective coating, and inhibiting moisture accumulation. Ensure even coverage, and use a product specifically designed for brake components to create a protective barrier against corrosion.

Wrap the Rotors Individually with Paper:

Provide an extra layer of protection by individually wrapping each rotor with paper. This helps prevent surface contact between rotors, minimizing the risk of scratches or damage during storage.

Place into a Sealed Plastic Bag/Ziplock Bag:

Shield your brake rotors from the effects of humidity by placing each individually wrapped rotor into a sealed plastic bag. If available, use a zip-lock bag. Ensure you have squeezed all the air out before zipping it shut to prevent moisture from reaching the rotor.

Keep in a Protective Box:

As a final step, place the sealed plastic bags containing the wrapped rotors into a protective box. This additional layer adds another level of defense, keeping your brake rotors safe and rust-free until you’re ready to use them again.

Following these steps ensures that your brake rotors remain in optimal condition during storage, ready to deliver peak performance when your vehicle hits the road again.

Periodic Quick and Efficient Rotor Inspections During Storage

To keep your classic car brake rotors in top shape during storage, you have to stay on top of things. Even when the brake rotor is taking a break under cover, they can still feel the effects of time. Regular check-ups are key to making sure these important parts stay in good condition. Make it a habit to spend a few minutes each month giving your brake rotors a once-over.

This simple routine helps protect them from pesky rust and keeps your whole brake system performing well for the long haul. It’s an easy way to ensure your car is ready to roll smoothly when it’s time to hit the road again.

Here is a checklist for quick and efficient rotor assessments.

- Visual Inspection: Check for any visible signs of rust, corrosion, grease, paint off, uneven wear, or any damage on the rotor surfaces.

- Protective Coating: Confirm the integrity of any applied corrosion inhibitor. Reapply as needed to maintain a barrier against rust.

- Brake Pad Residue: Ensure there’s no residual brake pad material that could contribute to corrosion.

- Storage Conditions: Confirm that the storage environment remains dry and adequately ventilated.

Brake Rotor Post-Storage Tips

The smooth comeback of your brake rotors depends on the proactive steps you took during storage. Those protective coatings, regular check-ups, and proper storage conditions of the brake disk all contribute to a trouble-free return.

However, it’s crucial to note that oil works as a lubricant while braking, which is absolutely the opposite of what we need on our brakes. So before we use the brake rotors, they need a thorough cleaning and some more care. Let’s know them.

Take out the brake rotor from the box, unwrap it, wipe down the brake dust, and visually inspect it. Look for any signs of damage, such as flat spots, rust, or corrosion, on the stored brake rotors. Addressing issues at this stage prevents potential complications later.

As we have used protective coatings during storage, now we have to gently remove them. Use an effective brake cleaner and thoroughly clean them to ensure the rotor is totally oil-free. Remember, oil can work against the rotor’s functionality, so it’s crucial to clean them thoroughly.

After cleaning, you can truly assess the actual condition of the rotors. Now you can see if there is some contamination or rust that also needs care. If there is light surface rust, they will go on their own after a few miles of driving. But for deep corrosion, warped rotors, or worn brake pads, you must think of replacing them.

Frequently Asked Question

Why do my brake rotors rust overnight?

Brake rotors can rust overnight due to the combination of moisture and the absence of frictional activity. Brake rotors are made of cast iron or steel and are highly at risk of developing rust just when they come into contact with any moisture. When your vehicle sits overnight, the humid weather of nighttime condensation forms on brake pads and rotor surfaces and develops rust.

Is It OK To Have Rusted Rotors?

Yes, it’s generally okay to have rusted rotors to some extent; regular driving eliminates minor rust and doesn’t impact braking performance. But if the rust is excessive or extends to the braking surface, it may affect braking efficiency.

However, if you notice a significant decrease in braking performance, unusual noises, or persistent rust, it’s advisable to have the brake disc rotors inspected and, if necessary, replaced for optimal safety and performance.

What Is The Lifespan Of Rotors?

The lifespan of rotors depends on their usability. Usually, a rotor can last from 30,000 miles to a maximum of 70,000. If you drive regularly, they may last around two and a half years. However, with frequent driving, the longevity of rotors can extend beyond this timeframe.

What Removes Rust From Rotors?

Regular driving and brake application can gradually wear off surface rust from the rotors if it’s minor rust. However, if there is deep rust, you need to use cleaning solvents like baking soda, vinegar, lemon juice, etc., or commercial cleaner to remove rust from rotors.

Brake Cleaner: Spray brake cleaner all over the rotor surface, scrub gently with a wire brush, and leave it overnight or as per the instruction manual. Clean and wipe.

Baking soda and toothpaste: Add some baking soda to toothpaste, apply it to the rotor surface, and scrub with a wire brush. Let it sit for 10–12 hours. Spray some brake cleaner or vinegar, scrub again with steel wool, and wipe away.

Vinegar or Lemon Juice: Apply a mixture of vinegar or lemon juice and water to the rusted areas. Let it sit for some time, then scrub or wipe it away.

Commercial Rust Removers: Commercial rust removal products are available and can be applied according to the product’s instructions.

How Do You Prevent Rotor Damage?

To prevent rotor damage, adopt these practices:

Ensure proper brake fluid levels and adhere to recommended replacement intervals.

Regularly check and replace brake pads before they wear down completely.

Minimize aggressive or sudden braking, which can generate excessive heat and stress on the rotors.

Ensure brake calipers are functioning correctly to prevent uneven rotor wear.

Follow manufacturer guidelines for proper bedding-in procedures when installing new brake components.

Limit carrying heavy loads to prevent unnecessary strain on the braking system.

Periodically inspect rotors for signs of wear, scoring, or abnormal conditions.

Conclusion

To conclude, preventing rust on brake rotors is crucial for maintaining the performance and longevity of your vehicle’s braking system. By understanding the causes of brake rotor rust and implementing proper storage solutions, such as keeping them in a dry and clean environment, using rust inhibitor spray, or using brake rotor covers, you can significantly reduce the risk of rust formation.

Regular inspection, proper cleaning, and drying are also essential preventive measures. By taking these steps to prevent rust, you can save money on costly rotor replacements and ensure your brakes stay in optimal condition.

Remember, surface rust can often be treated, but deep rust may require rotor replacement. Don’t fall for common myths and misconceptions; prioritize proper storage and maintenance to keep your brake rotors rust-free for safer driving.